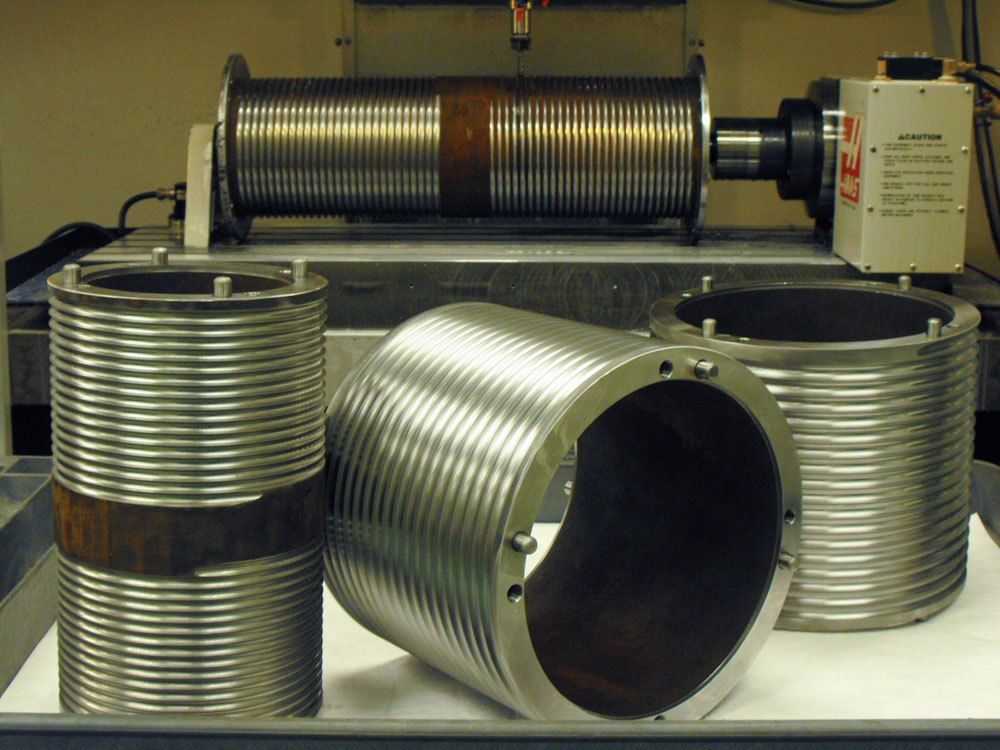

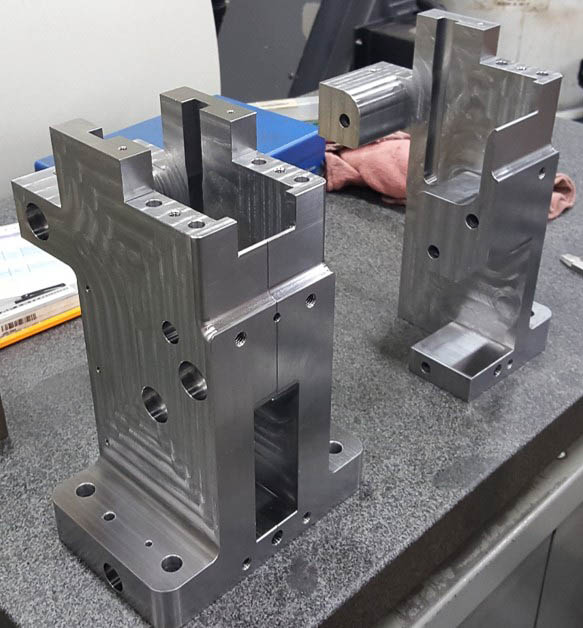

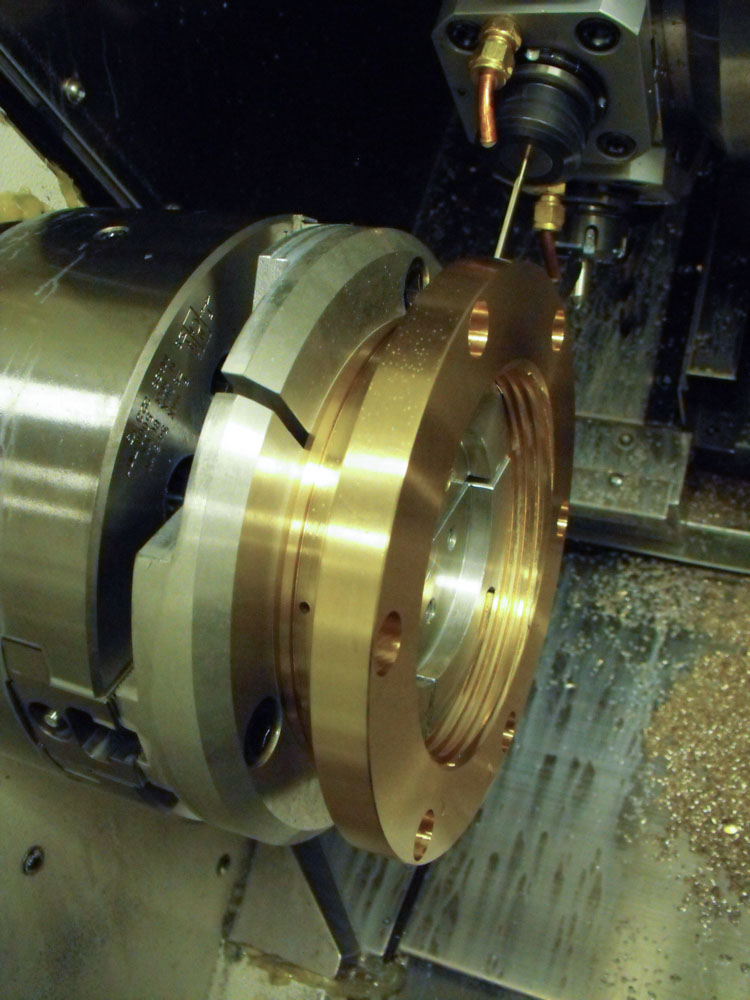

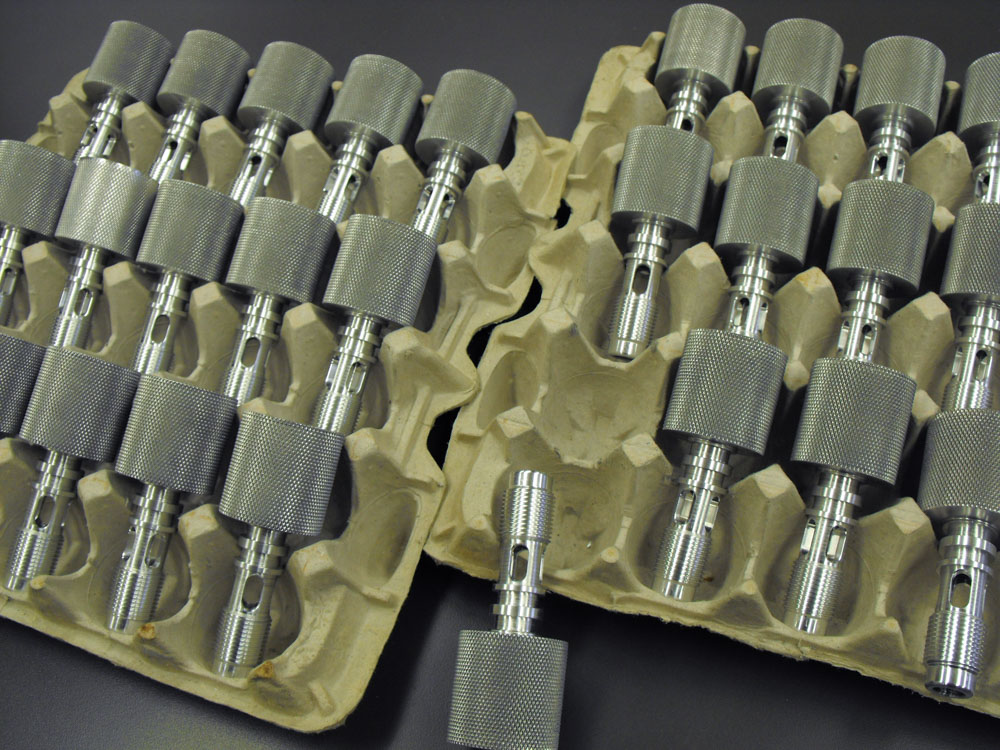

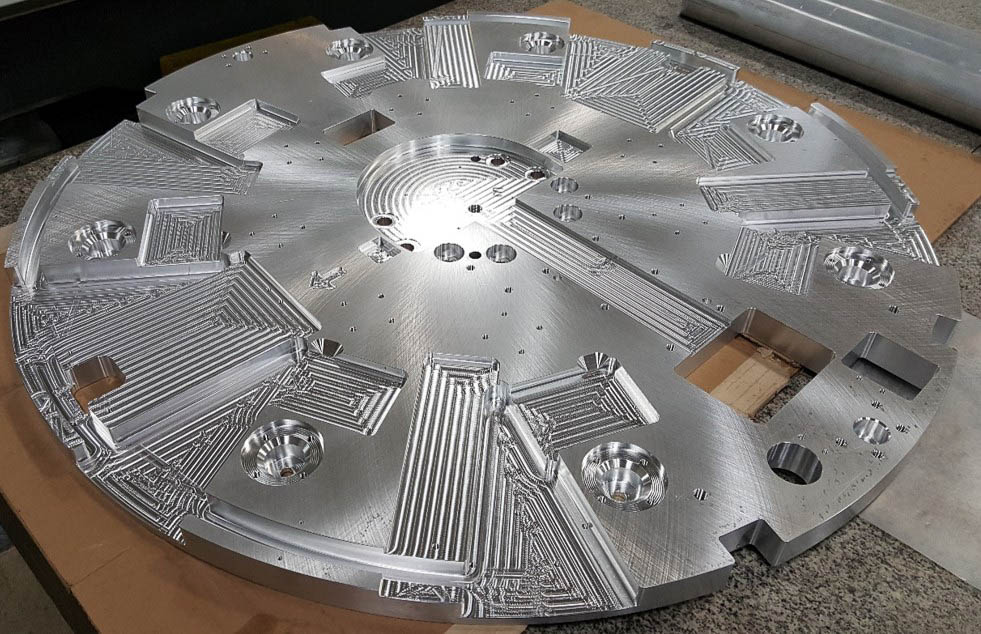

EDCO, INC. offers precision machining capabilities for products and components in steel and steel alloys, stainless steel, aluminum and other soft metals, plastics and composites. Our CNC and manual machining centers support production projects as well as supplying specific machined products for our customers. We accommodate short and long run production, one-off parts, prototyping, fixture making and machining of fabricated parts.

OUR MACHINING CAPABILITIES

- Our lathe capabilities include: turning, boring, drilling, tapping, internal and external threading, grooving and part-off.

- Our mill capabilities include: horizontal and vertical milling, facing, profiling, drilling, tapping, boring, surfacing, full 4th axis machining and thread milling.

- We can finish your machined parts with vibratory tumbling, polishing and de-burring.

OUR MACHINING RESOURCES INCLUDE

- Nakamura 9 Axis Machining Center – 8″ Dia. x 22″

- Haas VF9 4 Axis Vertical Machining Center – 84″ x 40″ x 30″

- Haas VF6/50 Axis Vertical Machining Center – 64″ x 32″ x 30″

- Haas VF4 4 Axis Vertical Machining Center – 50″ x 20″ x 26″

- Haas VF2 4 Axis Vertical Machining Center – 30″ x 20″ x 24″

- Hitachi Seiki Hitec-Turn 20J Lathe – 8″ Dia. x 14″

- Wells Index #2 Vertical Mills w/Digital Readout – 32.3″ x 11.25″

- CNC ProtoTRAK Bed Mill – 31″ x 16″ x 23.5″

- Poreba Engine Lathe w/Digital Readout – 38″ Dia. x 168″

- Graziano Engine Lathe – 16″ Dia. x 48″

- Faro Arm

- Laser Tracker