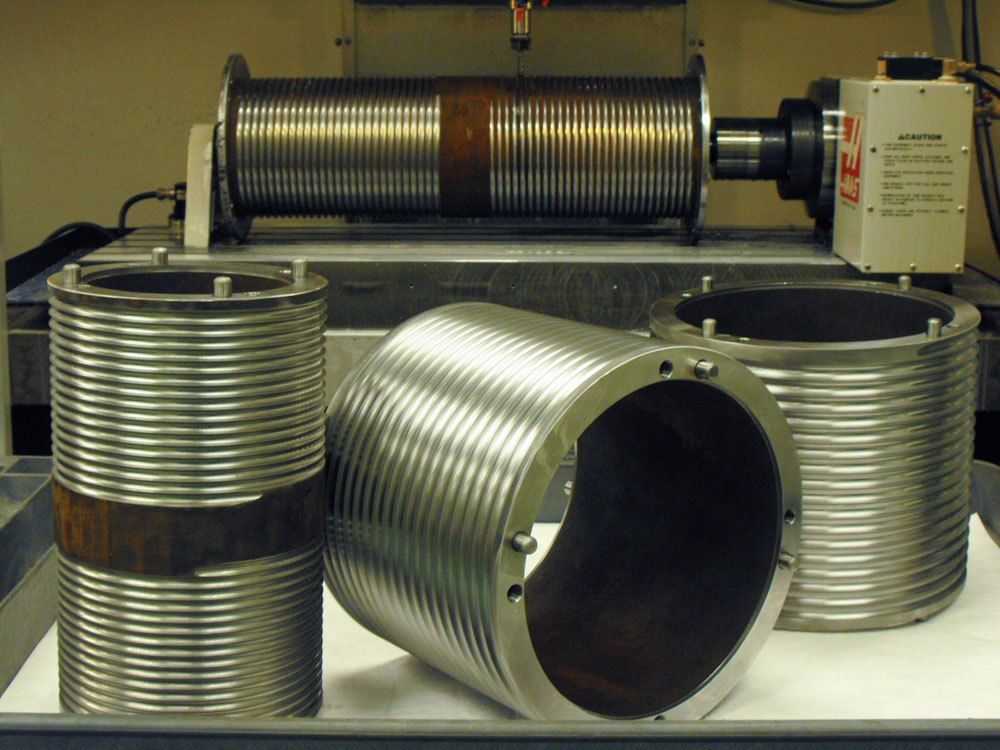

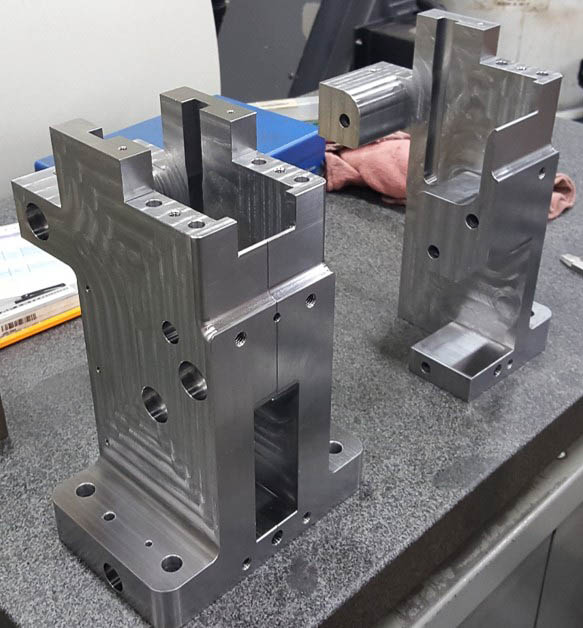

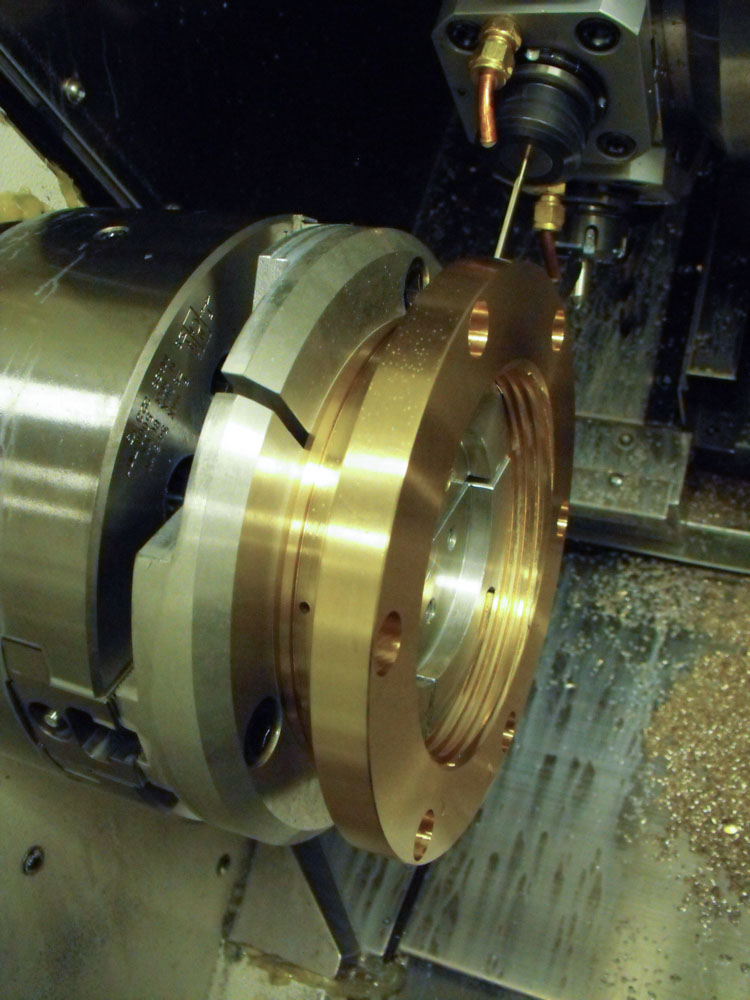

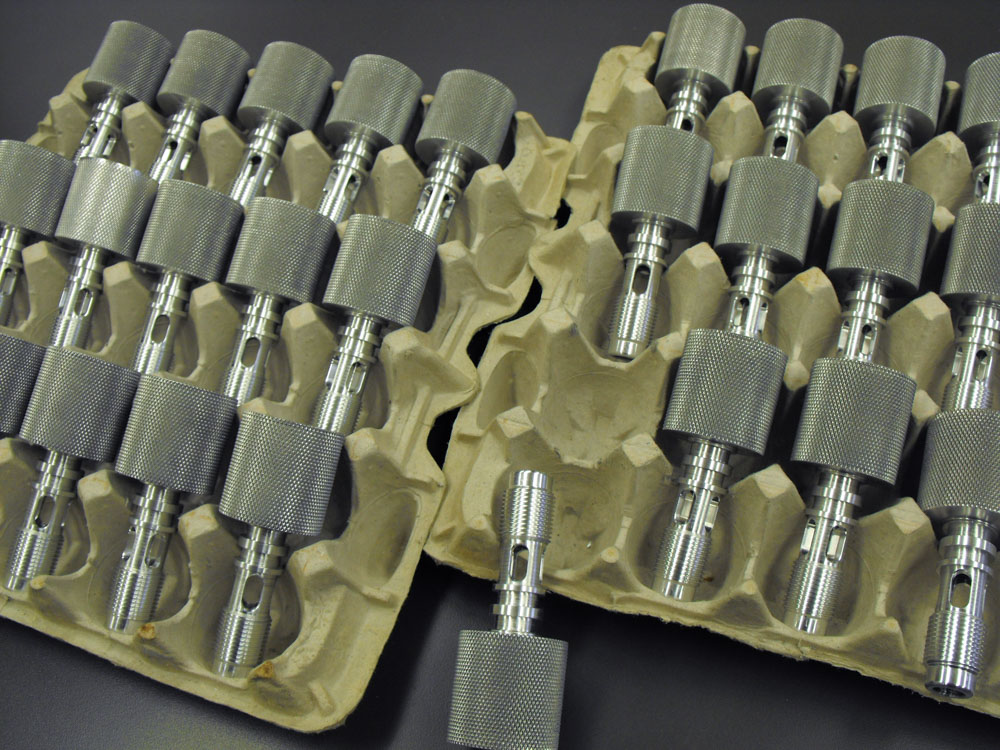

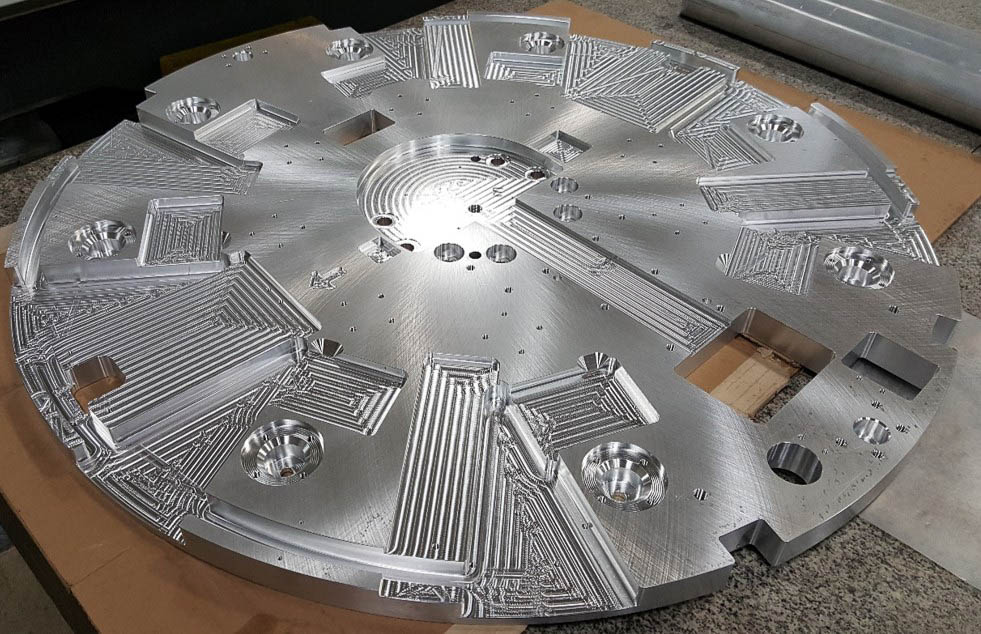

At EDCO, we are experts in precision machining, working with a variety of materials such as steel, steel alloys, stainless steel, aluminum, soft metals, plastics, and composites. Our advanced CNC and manual machining centers are equipped to handle everything from short and long production runs to one-off parts, prototypes, fixture fabrication, and machining of pre-fabricated components. We are committed to maintaining the highest quality standards for every project.

Why Choose EDCO for Machining?

- Extensive Industry Experience

With years of hands-on experience, the EDCO team brings unmatched knowledge and expertise to every project. Our efficient processes and commitment to precision ensure quick turnaround times and consistently accurate parts. Our proven track record highlights the reliability and quality of our machining services. - Versatile Material Handling

At EDCO, we excel in working with a wide range of materials, from hardened steels to lightweight plastics. With the right tools and expertise, we guarantee precise results, ensuring every component meets your exact specifications. - Scalable Production

Whether you need a one-off prototype or large-scale production, EDCO is equipped to handle projects of any size. We offer efficient, flexible, and cost-effective machining solutions tailored to meet your unique requirements.

Comprehensive Machining Capabilities

- Lathe Operations

We specialize in high-precision lathe operations, including turning, boring, drilling, tapping, internal and external threading, grooving, and part-off. Every process is executed with exceptional attention to detail, ensuring accurate and reliable results. - Milling Operations

Our milling services feature both horizontal and vertical milling, as well as advanced capabilities such as facing, profiling, drilling, tapping, boring, surfacing, full 4th-axis machining, and thread milling. With this extensive skill set, we can tackle even the most intricate and complex designs with ease. - Finishing & Deburring

We deliver superior finishing services, including vibratory tumbling, polishing, and de-burring, to ensure your machined parts are flawless. Each component is polished, refined, and ready for immediate use, providing you with a high-quality finish you can trust.

Advanced Machining Resources

- Haas VF9 4-Axis Vertical Machining Center – 84″ x 40″ x 30″

- Haas VF6/50 Axis Vertical Machining Center – 64″ x 32″ x 30″

- Haas VF4 4-Axis Vertical Machining Center – 50″ x 20″ x 26″

- Haas VF2 4-Axis Vertical Machining Center – 30″ x 20″ x 24″

- Haas ST30 Lathe

- Hitachi Seiki Hitec-Turn 20J Lathe – 8″ Dia. x 14″

- CNC ProtoTRAK Bed Mill – 31″ x 16″ x 23.5″

- Poreba Engine Lathe w/Digital Readout – 38″ Dia. x 168″

- Graziano Engine Lathe – 16″ Dia. x 48″

- Faro Arm

- Laser Tracker

In addition, these top-of-the-line machines help us deliver outstanding results every time, streamlining production processes and ensuring reliable outcomes.

Get Started with EDCO Today

Experience the difference our EDCO machining capabilities bring to your next project. In particular, from precision CNC machining to manual operations and finishing, we provide end-to-end solutions tailored to your specific requirements. Contact us now for a quote and discover how our commitment to quality can elevate your products and components.